In part one of this blog, we shared our journey to align Stahl’s science-based emissions reduction targets with the 2015 Paris Agreement. Getting our targets validated by the Science Based Targets initiative (SBTi) was a great start, but there’s plenty of work still to do! Read on to discover some of the ways we are continuing to reduce the environmental impact of our company’s activities.

Scope 1 and 2: starting close to home

As per our first SBTi-validated target, Stahl has committed to reducing our Scope 1 and 2 greenhouse gas (GHG) emissions by 42% (in absolute terms) by 2030 compared with the 2021 base year. This target requires us to reduce our so-called “direct emissions” – those that are caused by burning fuels at our facilities and in our company-owned vehicles. Scopes 1 and 2 also cover the GHG emissions generated by producing all the electricity, steam, heating, and cooling used at our facilities.

We’re lowering our Scope 1 and 2 emissions in two important ways, firstly by reducing our overall energy consumption. To achieve this, we’re carefully monitoring how we use energy at our sites and other facilities and using the data to help us identify potential areas for energy savings. Based on this research, we then devise tailored energy-saving strategies and put them into practice. We’re also continuously investing in energy-saving equipment to help us reduce our overall energy intensity – that’s the total energy consumed per volume of product manufactured.

Second, we’re accelerating our transition to renewable energy – and that starts by using purchased lower-impact energy from the grid. For instance, all of Stahl’s manufacturing sites in Europe already purchase 100% of their electricity from renewable sources, as do our facilities in Brazil and Singapore.

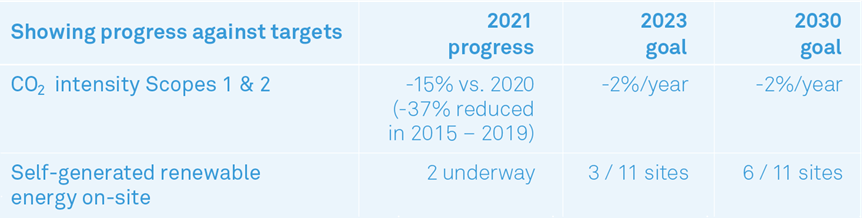

In addition, we’re steadily upgrading our sites to be more self-sufficient in energy, running on purpose-built on-site renewable energy sources. As outlined in Stahl’s ESG Roadmap to 2030, we aim to have on-site self-generated renewable energy at six of Stahl’s facilities by 2030. The energy generated by these sources is predicted to meet at least 20% of the sites’ power needs.

Powering up with solar

In 2022, we took two major steps toward achieving this goal. In June, we inaugurated a solar energy plant at our Mexican production site, the second Stahl site after Brazil (2018) to use this form of energy generation. Our Mexico site aims to meet 52% of its electricity needs from the sun alone, using 1,016 solar modules, and eight inverters – with an installed capacity of 554 kWp (kilowatt peak).

But this wasn’t the only major solar project taking shape in 2022. In October, we completed the installation of a new ground-mounted solar plant at Stahl's Kanchipuram site in India. These two projects helped raise the share of renewable energy in Stahl's overall energy mix to 42%, up from 38% in 2021.

In addition to our own on-site solar energy plants, we’re finding other ways to increase the amount of clean energy we use. In May 2022, Stahl’s Center of Excellence in León, Mexico, installed two solar water heaters in the upper part of the building. The following month, Stahl Italy began using a new solar-powered heating system for two of its buildings. This means that the hot water needed for sanitation in laboratories and other facilities can be heated without the use of a gas boiler.

Scope 3: transitioning to lower-impact feedstocks

Stahl’s Scope 3 emissions account for more than 90% of our total greenhouse gas emissions. Of these, the majority relate to the raw materials, purchased from our suppliers, that go into our products. Our target is set accordingly: we aim to reduce our absolute Scope 3 GHG emissions related to purchased goods and services by 25% by 2030, compared with the 2021 base year.

Therefore, our Scope 3 emissions reduction strategy focuses on replacing the fossil-based raw materials used in our products with lower-impact alternatives. These include renewable feedstocks, such as bio-based materials and recycled-based materials, as well as carbon dioxide captured from industrial processes. Across Stahl, we are working to ensure that all new products developed use the lowest-impact raw materials at our disposal.

Remaining accountable through organizational change

In 2022, we launched our Scope 3 Reduction Project to drive progress toward our emissions reduction targets. Three specially created working groups oversee the project. They are responsible for reporting on the benefits of replacing specific categories of raw materials used in our processes with lower-carbon alternatives.

Each working group covers a specific business area. The focus areas are polyols, acrylics and isocyanates, solvents, packaging, and wet-end chemicals. Every group is tasked with advising Stahl on which new raw materials to introduce into our product development process. Decisions are based on each material’s impact on our Scope 3 emissions, as well as its performance.

Another key aspect of Scope 3 emissions reduction is catalyzing a more transparent coatings value chain. Therefore, we collect life cycle assessment (LCA) data that covers all aspects of a product’s creation, even the indirect raw materials that go into the feedstocks we buy. Over the past few years, we’ve been focusing more and more on measuring the emissions linked to these indirect raw materials – helping us better understand the overall environmental impact of our products.

We also recently added a new position in our ESG team: Supply Chain Transparency Manager. This reflects our continued focus on both making our own value chain more transparent and catalyzing greater transparency throughout the industry. Because the more transparent we are, the more effectively we can reduce our Scope 3 emissions. Stahl now has LCA data for 160 of our products, and we aim to have this data for 300 products by 2030.

Let’s keep the momentum going

We’re making steady progress against our GHG emission reduction targets. Between 2015 and 2019, Stahl’s Scope 1 and 2 emissions fell by more than 30% in absolute terms. This was followed by a 15% and 24% year-on-year reduction in our absolute Scope 1 and Scope 2 emissions, respectively. Meanwhile, Stahl’s upstream Scope 3 GHG emissions fell by 23% year-on-year in 2022.

This reduction was partly the result of our purchasing fewer goods and services from suppliers than in the previous year. Nevertheless, it shows that we are firmly on track to meet our Scope 3 emissions reduction target by the end of the decade.

The window of opportunity to achieve the Paris Agreement’s 1.5°C target is rapidly closing. That means there is no time for companies like Stahl to take their foot off the pedal when it comes to lowering their environmental impact. And independently verified science-based targets play an important part in this journey. They enable companies and institutions to quantify their efforts and measure their progress toward building a low-carbon society. They help to bring clarity and transparency to all our climate ambitions.

The more companies from emissions-intensive industries that take the leap and get their targets validated, the quicker we can move forward, together.

Want to learn more?

- Get the full story about Stahl’s environmental efforts our Stahl 2022 ESG Report.

- Missed part 1 of our SBTi journey, read it here.

- Our ESG journey: all roads lead to 2030

- Scope 1, scope 2, and scope 3 carbon emissions: what are they?

- EcoVadis: Our journey to platinum

- Welcome to the great materials ‘Squid Game’

- Sustainable development